an Pump Machinery High Pressure Bareshaft Slurry Pump

Basic Info

Model No.: AM

Product Description

Model NO.: AM Max.Capacity: >400 L/min Impeller Number: Single-Stage Pump Influent Type of Impeller: Single Suction Pump Pump Casing Combined: Horizontal Split Pumps Impeller: Closed Pump Type: Centrifugal Slurry Pump Features: Abrasive Resistant Pump Pump Head: 5 - 125 M Pump Material: High Cr Mo Ni Alloy and Rubber Liner OEM: Available Specification: ISO, SGS, CE HS Code: 841370 Max.Head: 110m-150m Driving Type: Motor Working Pressure: High Pressure Pump Position of Pump Shaft: Horizontal Pump Mounting Height: Suction Centrifugal Usage: Pump Pump Size: From 1 Inch to 24 Inch Pump Capacity: 10 - 5400 M3/Hr Seal Type: Gland Seal, Expeller, Mechanical Seal Motor Driven: Electric Motor and Diesel Engine Trademark: An Pump Machinery Origin: Shijiazhuang City, China

General

AM series is horizontal, cantilevered centrifugal slurry pump, with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive or / and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building, etc. Especially well accepted by coal / chrome washing plant, mineral processing plant, power plant etc.

Design Features

Bearing assembly - A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

Liners - Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

Casing - Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

Impeller - Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

Throat bush - Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

One-piece frame - A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for

easy adjustment of impeller clearance.

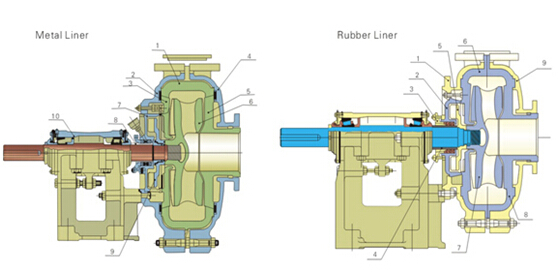

AM slurry pump Structure

AM Slurry Pump Performance Data

Applications

Chemical Process

Heavy Minerals

Paper and Pulp

Mill Discharge

Sugar Beet

Slag Granulation

Bottom Boiler and Fly Ash

Cyclone Feed

Power Utilities

Contact

Sherry Lee (Ms)

Tel: 0086 311 89940549

www.angroupcn.com

Anything thing need help, please call me any time, i will try best to help you. Contact us if you need more details on Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Slurry Pump、Heavy Duty Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

General

AM series is horizontal, cantilevered centrifugal slurry pump, with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive or / and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building, etc. Especially well accepted by coal / chrome washing plant, mineral processing plant, power plant etc.

Design Features

Bearing assembly - A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

Liners - Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

Casing - Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

Impeller - Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

Throat bush - Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

One-piece frame - A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for

easy adjustment of impeller clearance.

AM slurry pump Structure

| Metal liner | Rubber liner | ||

| 1 | Volute liner | 1 | Frame plate |

| 2 | Frame plate | 2 | Expeller ring |

| 3 | Frame plate liner insert | 3 | Gland assembly |

| 4 | Cover plate | 4 | Shaft sleeve |

| 5 | Throat bush | 5 | Expeller |

| 6 | Impeller | 6 | Frame plate liner |

| 7 | Expeller ring | 7 | Impeller |

| 8 | Shaft sleeve | 8 | Cover plate liner |

| 9 | Expeller | 9 | Cover plate |

| 10 | Bearing assembly | Note: Slurry pumps have Throat Bush from 4" | |

AM Slurry Pump Performance Data

| Model | Max Power (kw) | Material | Clear water performance | Impeller Vane No. | |||

| Liner | Impeller | Capacity Q ( m3/h) | Head H ( m) | Speed n (rpm) | |||

| 1.5/1B-AM | 15 | M | M | 12.6~28.8 | 6~68 | 1200~3800 | 5 |

| RU | RU | 10.8~25.2 | 7~52 | 1400~3400 | 3 | ||

| 1.5/1B-AMH | 30 | M | M | 16.2~34.2 | 25~92 | 1400~2200 | 5 |

| 2/1.5B-AM | 15 | M | M | 32.4~72 | 6~58 | 1200~3200 | 5 |

| RU | RU | 25.2~54 | 5.5~41 | 1000~2600 | |||

| 3/2C-AM | 30 | M | M | 39.6~86.4 | 12~64 | 1300~2700 | 5 |

| RU | RU | 36~75.6 | 13~39 | 1300~2100 | |||

| 4/3C-AM | 30 | M | M | 86.4~198 | 9~52 | 1000~2200 | 5 |

| 4/3D-AM | 60 | ||||||

| 4/3C-AM | 30 | RU | RU | 79.2~180 | 5~34.5 | 800~1800 | 5 |

| 4/3D-AM | 60 | ||||||

| 4/3E-AMH | 120 | M | M | 126~252 | 12~97 | 600~1400 | 5 |

| 6/4D-AM | 60 | M | M | 162~360 | 12~56 | 800~1550 | 5 |

| 6/4E-AM | 120 | ||||||

| 6/4D-AM | 60 | RU | RU | 144~324 | 12~45 | 800~1350 | 5 |

| 6/4E-AM | 120 | ||||||

| 6/4F-AMH | 260 | M | M | 100~414 | 34~98 | 600~1000 | 5 |

| 8/6E-AM | 120 | M | M | 360~828 | 10~61 | 500~1140 | 5 |

| 8/6E-AM | 120 | RU | RU | 324~720 | 7~49 | 400~1000 | 5 |

| 10/8ST-AM | 560 | M | M | 612~1368 | 11~61 | 400~850 | 5 |

| RU | RU | 540~1188 | 12~50 | 400~750 | |||

| 10/8E-MM | 120 | M | M | 666~1440 | 14~60 | 600~1100 | 5 |

| 10/8E-MM | 120 | RU | RU | 540~1188 | 10~42 | 500~900 | 5 |

| 12/10ST-AM | 560 | M | M | 936~1980 | 7~68 | 300~800 | 5 |

| M | M | 720~1620 | 7~45 | 300~650 | |||

| 14/12ST-AM | 560 | M | M | 1260~2772 | 13~63 | 300~600 | 5 |

| RU | RU | 1152~2520 | 13~44 | 300~500 | |||

| 16/14ST-AM | 560 | M | M | 1368~3060 | 11~63 | 250~550 | 5 |

| 16/14TU-AM | 1200 | ||||||

| 18/16ST-AM | 560 | M | M | 2160~5040 | 8~66 | 200~500 | 5 |

| 18/16TU-AM | 1200 | ||||||

| 20/18TU-AM | 1200 | M | M | 2520~5400 | 13~57 | 200~400 | 5 |

Applications

Chemical Process

Heavy Minerals

Paper and Pulp

Mill Discharge

Sugar Beet

Slag Granulation

Bottom Boiler and Fly Ash

Cyclone Feed

Power Utilities

Contact

Sherry Lee (Ms)

Tel: 0086 311 89940549

www.angroupcn.com

Anything thing need help, please call me any time, i will try best to help you. Contact us if you need more details on Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Slurry Pump、Heavy Duty Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Slurry Pump > AM slurry pump

Premium Related Products

Other Products

Hot Products

Centrifugal Zj Horizontal and Zjl Vertical Slurry PumpGravel Sand Pump for Dredger Mud PumpCentrifugal Mining Vertical Slurry Sump PumpHigh Pressure Boiler Feed Water PumpHeavy Duty High Pressure Mining Metal Lined Sludge Slurry PumpCentrifugal Horizontal High Pressure Multistage PumpSand Gravel Pump Marine Dredger Mud PumpHigh Abrasion and Corrosion Resistance Slurry PumpMultistage Centrifugal Water PumpFgd Pump (TLR)Stainless Steel Chemical Pump (IH)Pump AccessoriesFroth Slurry Pump for MiningDredger Gravel Slurry PumpPn Pnl Single Stage Single Suction Mud PumpPw, Pwl High Pressure Machinery Sewage Single Stage Centrifugal Pump