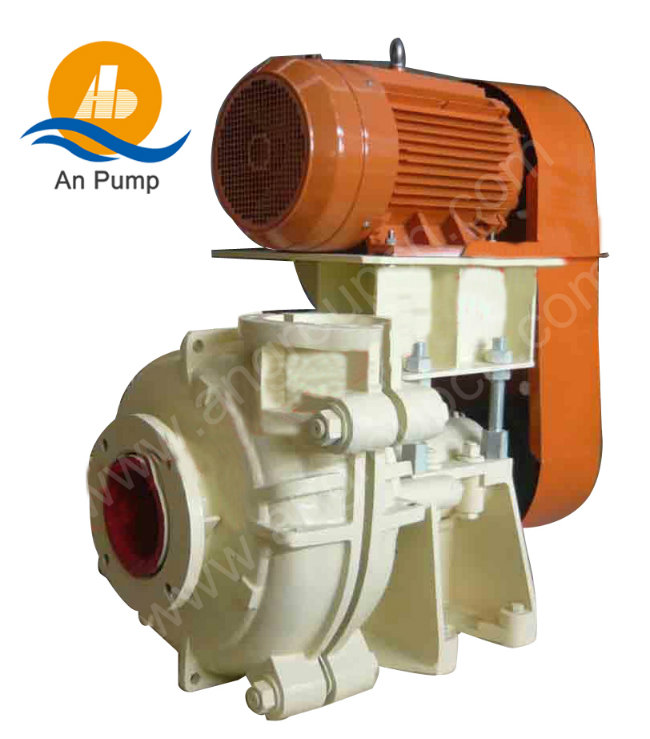

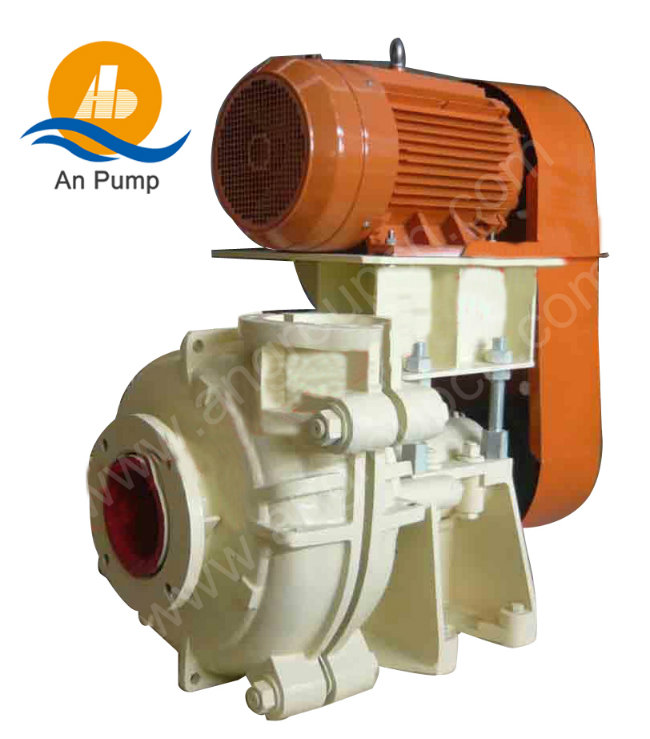

High Abrasion Resistance Coal Slurry Pump

Basic Info

Model No.: AM, AMH, AZ horizontal slurry pump

Product Description

Model NO.: AM, AMH, AZ horizontal Slurry Pump Max.Capacity: >400 L/min Impeller Number: Single-Stage Pump Influent Type of Impeller: Single Suction Pump Pump Casing Combined: Horizontal Split Pumps Impeller: Closed Size: 1"-24" Drive Type: DC, Cr, Zv, CV Seal Type: Packing Seal or Mechanical Seal Impeller Type: Closed Impeller No. of Impeller: 5 Vans Trademark: An Pump Origin: Hebei Max.Head: >150m Driving Type: Motor Working Pressure: Middle Pressure Pump Position of Pump Shaft: Horizontal Pump Mounting Height: Suction Centrifugal Usage: Pumps Material: High Chrome Alloy and Rubber Shaft Position From The Horizontal: Horizontal Slurry Pump Temperature: Ambient Impeller Suction Way: Single Suction Pump Other Application: Mining,Power Plant,Coal,Metallurgy,Building Materi Specification: CE, ISO, SGS HS Code: 8413709990 Shijiazhuang An Pump Machinery

Co., Ltd,the main pump products including slurry pump, desulfurization pump, gravel pump, sewage pump, impurity pump, split pump with large capacity, multistage pump with hjgh lift, centrifugal water pump and self priming pump, could meet various requirements of all the customers

AM centrifugal slurry pump are mainly used to pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc. Detailed specification: 1. Horizontal, cantilevered, centrifugal, single stage slurry pump 2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees 7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

AM Slurry pump performance data sheet

FAQ: 1.Q:Are you a factory or trading company?

FAQ: 1.Q:Are you a factory or trading company?

A:We are a factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 3.Q:What is The material of your products? A: The material is High chrome alloy or Rubber. We can also choose material as customers' requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20 QC. WE ARE THE FACTORY OF SLURRY PUMPS,GRAVEL PUMPS,SUMP PUMPS,WELCOME TO INQUIRE FROM US.WE WILL GIVE YOU LOWEST PRICE AND BEST QUALITY. Contact us if you need more details on Horizontal Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Slurry Pump、Rubber Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Co., Ltd,the main pump products including slurry pump, desulfurization pump, gravel pump, sewage pump, impurity pump, split pump with large capacity, multistage pump with hjgh lift, centrifugal water pump and self priming pump, could meet various requirements of all the customers

AM centrifugal slurry pump are mainly used to pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc. Detailed specification: 1. Horizontal, cantilevered, centrifugal, single stage slurry pump 2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees 7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

AM Slurry pump performance data sheet

| Model | Max Power | Material | Clear water performance | Impeller Vane No. | |||||

| Liner | Impeller | Capacity Q ( m3/h) | Head H ( m) | Speed n (rpm) | Eff. Η(%) | NPSH (m) | |||

| 1.5/1B-AM | 15 | M | M | 12.6~28.8 | 6~68 | 1200~3800 | 40 | 2~4 | 5 |

| RU | RU | 10.8~25.2 | 7~52 | 1400~3400 | 35 | 3 | |||

| 1.5/1B-AMH | 30 | M | M | 16.2~34.2 | 25~92 | 1400~2200 | 20 | 1~5.5 | 5 |

| 2/1.5B-AM | 15 | M | M | 32.4~72 | 6~58 | 1200~3200 | 45 | 3.5~8 | 5 |

| RU | RU | 25.2~54 | 5.5~41 | 1000~2600 | 50 | 2.5~5 | |||

| 3/2C-AM | 30 | M | M | 39.6~86.4 | 12~64 | 1300~2700 | 55 | 4~6 | 5 |

| RU | RU | 36~75.6 | 13~39 | 1300~2100 | 2~4 | ||||

| 4/3C-AM | 30 | M | M | 86.4~198 | 9~52 | 1000~2200 | 71 | 4~6 | 5 |

| 4/3D-AM | 60 | ||||||||

| 4/3C-AM | 30 | RU | RU | 79.2~180 | 5~34.5 | 800~1800 | 59 | 3~5 | 5 |

| 4/3D-AM | 60 | ||||||||

| 4/3E-AMH | 120 | M | M | 126~252 | 12~97 | 600~1400 | 50 | 2~5 | 5 |

| 6/4D-AM | 60 | M | M | 162~360 | 12~56 | 800~1550 | 65 | 5~8 | 5 |

| 6/4E-AM | 120 | ||||||||

| 6/4D-AM | 60 | RU | RU | 144~324 | 12~45 | 800~1350 | 65 | 3~5 | 5 |

| 6/4E-AM | 120 | ||||||||

| 6/4F-AMH | 260 | M | M | 100~414 | 34~98 | 600~1000 | 64 | 2~8 | 5 |

| 8/6E-AM | 120 | M | M | 360~828 | 10~61 | 500~1140 | 72 | 2~9 | 5 |

| 8/6E-AM | 120 | RU | RU | 324~720 | 7~49 | 400~1000 | 65 | 5~10 | 5 |

| 10/8ST-AM | 560 | M | M | 612~1368 | 11~61 | 400~850 | 71 | 4~10 | 5 |

| RU | RU | 540~1188 | 12~50 | 400~750 | 75 | 4~12 | |||

| 10/8E-MM | 120 | M | M | 666~1440 | 14~60 | 600~1100 | 73 | 4~10 | 5 |

| 10/8E-MM | 120 | RU | RU | 540~1188 | 10~42 | 500~900 | 79 | 5~9 | 5 |

| 12/10ST-AM | 560 | M | M | 936~1980 | 7~68 | 300~800 | 82 | 6 | 5 |

| M | M | 720~1620 | 7~45 | 300~650 | 80 | 2.5~7.5 | |||

| 14/12ST-AM | 560 | M | M | 1260~2772 | 13~63 | 300~600 | 77 | 3~10 | 5 |

| RU | RU | 1152~2520 | 13~44 | 300~500 | 79 | 3~8 | |||

| 16/14ST-AM | 560 | M | M | 1368~3060 | 11~63 | 250~550 | 79 | 4~10 | 5 |

| 16/14TU-AM | 1200 | ||||||||

| 18/16ST-AM | 560 | M | M | 2160~5040 | 8~66 | 200~500 | 80 | 4.5~9 | 5 |

| 18/16TU-AM | 1200 | ||||||||

| 20/18TU-AM | 1200 | M | M | 2520~5400 | 13~57 | 200~400 | 85 | 5~10 | 5 |

FAQ: 1.Q:Are you a factory or trading company?

FAQ: 1.Q:Are you a factory or trading company? A:We are a factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 3.Q:What is The material of your products? A: The material is High chrome alloy or Rubber. We can also choose material as customers' requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20 QC. WE ARE THE FACTORY OF SLURRY PUMPS,GRAVEL PUMPS,SUMP PUMPS,WELCOME TO INQUIRE FROM US.WE WILL GIVE YOU LOWEST PRICE AND BEST QUALITY. Contact us if you need more details on Horizontal Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Slurry Pump、Rubber Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Slurry Pump > Others Slurry pump

Premium Related Products

Other Products

Hot Products

Centrifugal Zj Horizontal and Zjl Vertical Slurry PumpGravel Sand Pump for Dredger Mud PumpCentrifugal Mining Vertical Slurry Sump PumpHigh Pressure Boiler Feed Water PumpHeavy Duty High Pressure Mining Metal Lined Sludge Slurry PumpCentrifugal Horizontal High Pressure Multistage PumpSand Gravel Pump Marine Dredger Mud PumpHigh Abrasion and Corrosion Resistance Slurry PumpMultistage Centrifugal Water PumpFgd Pump (TLR)Stainless Steel Chemical Pump (IH)Pump AccessoriesFroth Slurry Pump for MiningDredger Gravel Slurry PumpPn Pnl Single Stage Single Suction Mud PumpPw, Pwl High Pressure Machinery Sewage Single Stage Centrifugal Pump