Centrifugal Wear Resistant Barge Sand High Pressure Drilling Mud Dredge Pump

Basic Info

Model No.: AMG Mud pump

Product Description

Model NO.: AMG Mud Pump Max.Capacity: 30000m3/H Impeller Number: Single-Stage Pump Influent Type of Impeller: Single Suction Pump Pump Casing Combined: Horizontal Split Pumps Impeller: Semi-Open Mud Pump Condition: New Trademark: An Pump Origin: China Max.Head: 80-110m Driving Type: Motor Working Pressure: High Pressure Pump Position of Pump Shaft: Horizontal Pump Mounting Height: Suction Centrifugal Usage: Pump Mud Pump Driver: Diesel Engine or Electrical Motor Specification: Class One HS Code: 841370 Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Overview about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

AMG/AMGH sand gravel mud pumps, Construction of this pump is of single casing connected by means of clamp bands and wide wet passage. The wet parts are made of Ni hard and high chromium abrasion resistance alloys.

Details about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

The discharge direction of pump can be oriented in any direction of 360 degrees.

This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance

Drive types includes V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc.

AMG/AMGH gravel mud pump are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries

in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type AMGH pumps are of high head ones

Generals about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

AMG/AMGH river dredge sand pumps.

Construction of this pump is of single casing connected by means of clamp bands and wide wet passage.

The wet parts are made of Ni hard and high chromium abrasion resistance alloys.

The discharge direction of Sand Pump can be oriented in any direction of 360 degrees.

This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.

Drive types for Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc.

AMG/AMGH sand pump is designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurry

in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type AMGH pumps are of high head ones

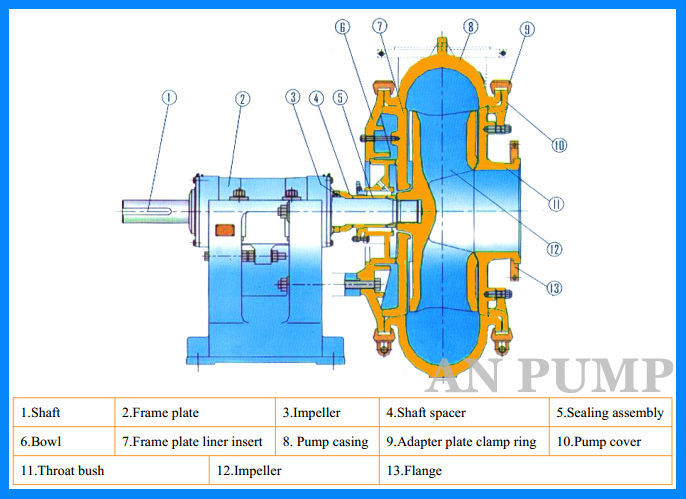

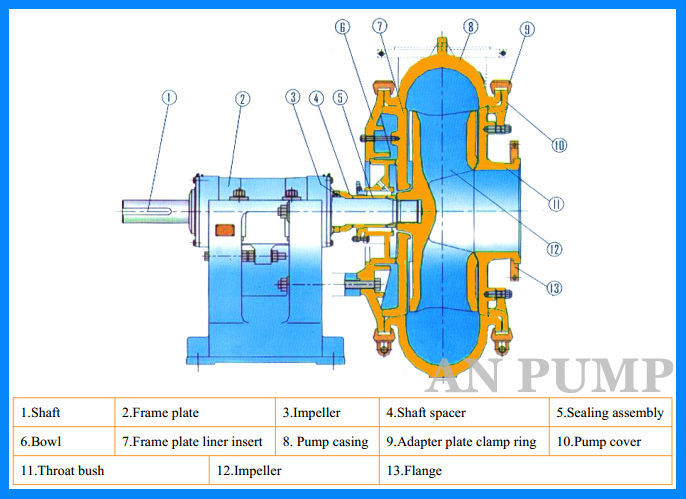

Structural Features about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

- Single stage, single suction, horizontal centrifugal sand pump

- Wet parts such as casing, impeller, liner plate in anti-abrasion high chrome cast iron alloy.

- Horizontal-central-split container bracket easy for maintaining

- Packing or mechanical seal

- Protective shell surrounding the casing ideal for heavy duty

- Hydraulic optimization design, high-efficient, energy-saving and stable operation

Construction about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Application about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Heavy duty Mining Process Coal Preparation Plant

Cyclone Feeds Mineral Processing

Tailings Mill Grinding

Slurry Feeding System Heavy Refuse Removal

Pulp And Paper Dredging

Abrasive Slurry High Density Slurries

Ash Handling Industrial Processing

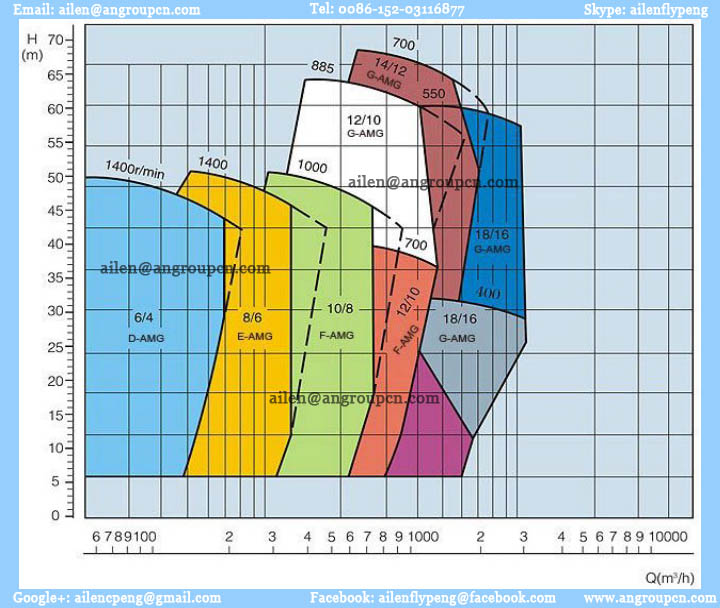

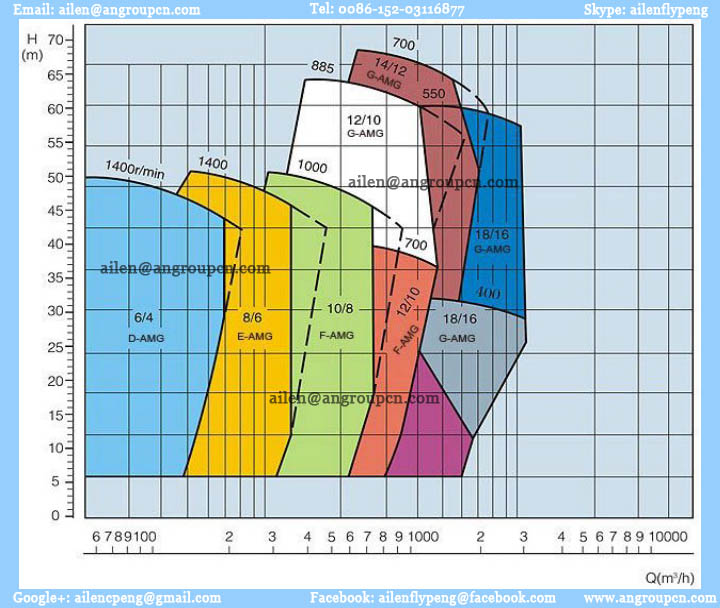

Performance about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

RFQ about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Tips for sand pump installation

Please take note as below when install the sand pump:

1. The preformed hole on the foundation should be poured as the pump installation drawing.

2. The installation level should meet the demand of the allowed vacuum suction height. The foundation should be in horizontal and stable condition, to make sure the rotation of the driver machinery same with the pump in the direction.

3. When connect by coupling, must make sure the pump and driver shaft center should be in a straight line.

4. If belt connection, the shaft center should be in parallel.

5. The sand pump suction pipe should be sealed well, and try to less the quantity of the elbow and check valve. When fill water, exhausted the air. It should be no any air when operate. We need to keep the suction pipe slopes up slightly, and then connect with the pump inlet. Contact us if you need more details on Dredge Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mud Pump、Drilling Mud Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Overview about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

AMG/AMGH sand gravel mud pumps, Construction of this pump is of single casing connected by means of clamp bands and wide wet passage. The wet parts are made of Ni hard and high chromium abrasion resistance alloys.

Details about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

The discharge direction of pump can be oriented in any direction of 360 degrees.

This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance

Drive types includes V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc.

AMG/AMGH gravel mud pump are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries

in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type AMGH pumps are of high head ones

Generals about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

AMG/AMGH river dredge sand pumps.

Construction of this pump is of single casing connected by means of clamp bands and wide wet passage.

The wet parts are made of Ni hard and high chromium abrasion resistance alloys.

The discharge direction of Sand Pump can be oriented in any direction of 360 degrees.

This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.

Drive types for Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc.

AMG/AMGH sand pump is designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurry

in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type AMGH pumps are of high head ones

Structural Features about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

- Single stage, single suction, horizontal centrifugal sand pump

- Wet parts such as casing, impeller, liner plate in anti-abrasion high chrome cast iron alloy.

- Horizontal-central-split container bracket easy for maintaining

- Packing or mechanical seal

- Protective shell surrounding the casing ideal for heavy duty

- Hydraulic optimization design, high-efficient, energy-saving and stable operation

Construction about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Application about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Heavy duty Mining Process Coal Preparation Plant

Cyclone Feeds Mineral Processing

Tailings Mill Grinding

Slurry Feeding System Heavy Refuse Removal

Pulp And Paper Dredging

Abrasive Slurry High Density Slurries

Ash Handling Industrial Processing

Performance about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

RFQ about Centrifugal Wear Resistant Dredge Pump Barge Sand High Pressure Drilling Mud Pump

Tips for sand pump installation

Please take note as below when install the sand pump:

1. The preformed hole on the foundation should be poured as the pump installation drawing.

2. The installation level should meet the demand of the allowed vacuum suction height. The foundation should be in horizontal and stable condition, to make sure the rotation of the driver machinery same with the pump in the direction.

3. When connect by coupling, must make sure the pump and driver shaft center should be in a straight line.

4. If belt connection, the shaft center should be in parallel.

5. The sand pump suction pipe should be sealed well, and try to less the quantity of the elbow and check valve. When fill water, exhausted the air. It should be no any air when operate. We need to keep the suction pipe slopes up slightly, and then connect with the pump inlet. Contact us if you need more details on Dredge Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mud Pump、Drilling Mud Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Sand Gravel Pump > Others Sand Gravel Pump

Other Products

Hot Products

Centrifugal Zj Horizontal and Zjl Vertical Slurry PumpGravel Sand Pump for Dredger Mud PumpCentrifugal Mining Vertical Slurry Sump PumpHigh Pressure Boiler Feed Water PumpHeavy Duty High Pressure Mining Metal Lined Sludge Slurry PumpCentrifugal Horizontal High Pressure Multistage PumpSand Gravel Pump Marine Dredger Mud PumpHigh Abrasion and Corrosion Resistance Slurry PumpMultistage Centrifugal Water PumpFgd Pump (TLR)Stainless Steel Chemical Pump (IH)Pump AccessoriesFroth Slurry Pump for MiningDredger Gravel Slurry PumpPn Pnl Single Stage Single Suction Mud PumpPw, Pwl High Pressure Machinery Sewage Single Stage Centrifugal Pump