Centrifugal High Pressure Multistage Hot Water Pump

Basic Info

Model No.: speed 1450 to 2950 rpm multistage hot water pump

Product Description

Model NO.: speed 1450 to 2950 rpm multistage hot Water Pump Max.Capacity: 500m3/H Material: Cast Iron Assembly: Booster Pump Start Up: Electric Pump Application: Clarified Water Pump, Sewage Pump, Chemical Pump, Boiler Pump Media: Water Pump Theory: Centrifugal Pump Hot Water Centrifugal Pump Driver: Electrical Motor or Diesel Engine Feature: Multistage Specification: Class One HS Code: 841370 Max.Head: 1000m Driving Type: Motor Structure: Multistage Pump Power: Electric Type: Positive-Displacement Pump Industry: Boiler Pump Performance: No Leakage Pump Condition: New Hot Water Centrifugal Pump Connect: Belt or Coupling Trademark: An Pump Origin: China Centrifugal High Pressure Multistage Hot Water Pump

=== GENERALS ===

General about Centrifugal High Pressure Multistage Hot Water Pump

QDG series boiler feed high pressure hot water centrifugal pump is multi-stages centrifugal pump. It used for boiler water feed or other industry hot water supply projects.

QDG series boiler feed hot water centrifugal pump matches the performance, technical requirement and testing method for the international boiler projects.

This series hot water centrifugal pump meet the international standard, with the feature of small volume, good performance, stable and reliable operation, and high efficiency. Besides, it is the best choice for the hot water supply projects.

It included horizontal Boiler Feed Water Pump and vertical boiler Feed Water Pump.

QDG series booster pump is multi-stages centrifugal pump. It used for boiler water feed or other industry hot water supply projects.

QDG series hot water centrifugal pump matches the performance, technical requirement and testing method for the international boiler projects.

This series boiler booster high pressure water pump meet the international standard, with the feature of small volume, good performance, stable and reliable operation, and high efficiency. Besides, it is the best choice for the hot water supply projects.

It included horizontal boiler feed water boiler feed water pump and vertical boiler feed water pump.

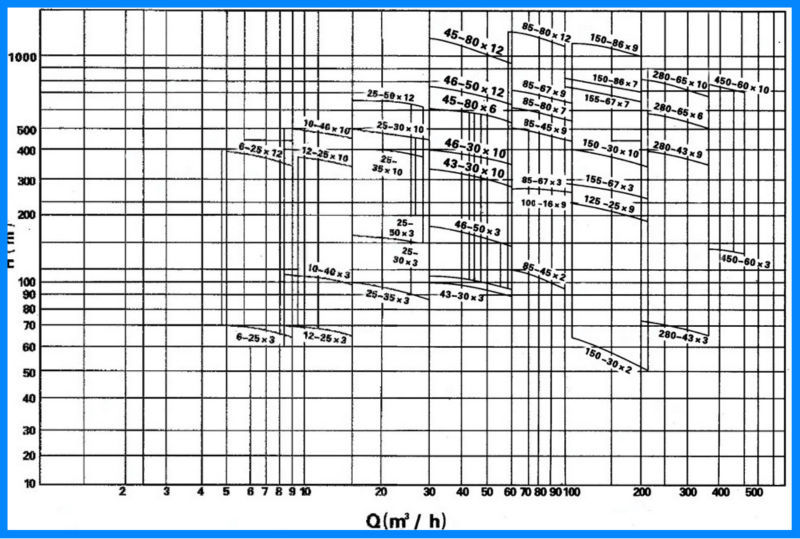

=== PARAMETER ===

Performance Range for Centrifugal High Pressure Multistage Hot Water Pump

Flow rate: 3~500m3/h

Head: 70~650m

Pressure: 7~65Bar

Speed: 1450~2950rpm

Max Eff: 90%

=== APPLICATION ===

Application for Centrifugal High Pressure Multistage Hot Water Pump

Aerospace Oil & Gas

Building industry Power Station

Chemical Petro-Chemical

General Industry Pharmaceutical

Marine Pulp & Paper

Mining & Aggregate Water & Waste water

=== ADVANTAGES ===

Advantages of Centrifugal High Pressure Multistage Hot Water Pump

20 years in producing horizontal boiler feed high pressure hot water centrifugal pump

Independent Design

advanced technology from Australia, Canada, America

Specialized Test Equipment

Anti-rust treatment casting

Supply reasonable suggestion for choosing pumps

OEM available

=== PERFORMANCE TABLE LIST ===

Performance Data Sheet for Centrifugal High Pressure Multistage Hot Water Pump

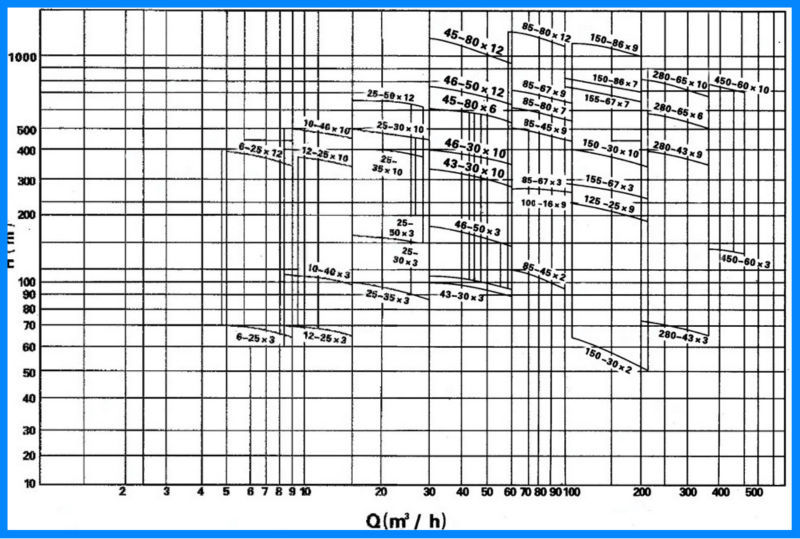

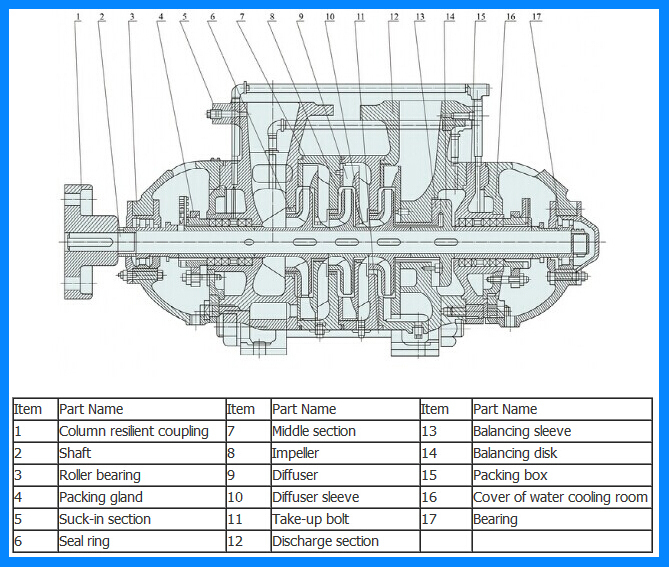

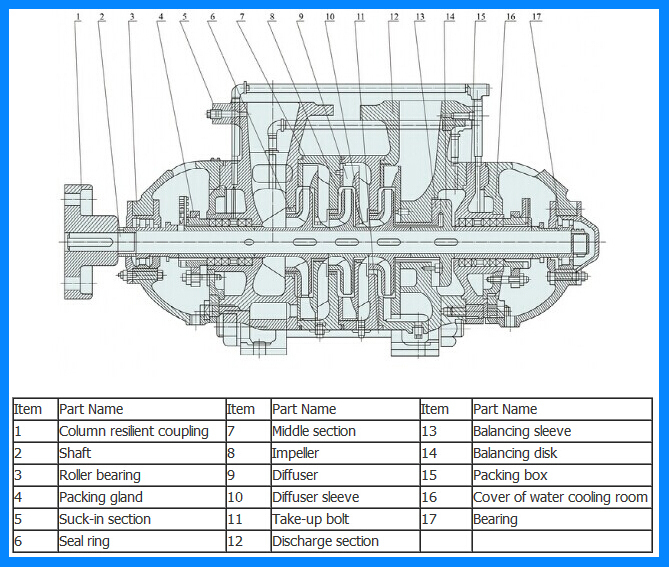

=== CURVE CHART === Performance curve chart about Centrifugal High Pressure Multistage Hot Water Pump  === CONSTRUCTION DRAWING === Construction drawing about Centrifugal High Pressure Multistage Hot Water Pump

=== CONSTRUCTION DRAWING === Construction drawing about Centrifugal High Pressure Multistage Hot Water Pump  === CONSTRUCTION FEATURE === Construction feature about Centrifugal High Pressure Multistage Hot Water Pump The Stainless Steel Housing Material and Free standing Installation heat pump swimming pool heater is supported by both ends, and casing portion is sectional. Connected with motor by flexible coupling For rotating direction, viewing from the motor end. 1. The boiler feedwater pumps are sectional casing,multistage centrifugal pumps. The suction casing, stage casing and discharge casings are rigidly held together by tie bolts. The joints between these casings are primarily sealed by means of metal-metal contact. Simultaneously,O-rings are used as auxiliary seals. 2. The shafts of these pumps are sealed by soft-packing and cooling water. Mechanical seal can be used according to the client's requirement. 3. The rotating assembly is supported by sliding bearings on both ends of the pump shaft. Bearings of pump are forced-lubricated. The oil system is equipped for type QD(G) pump The axial thrust of rotor is balanced by balance disc. And the thrust bearing is also provided which is sed to bear residual axial force caused by the change of working conditions. The assembly quality of the boiler feedwater pump will result in a notable affection to the performance and the running stability of it and can not be guaranteed unless the technical requirements in the drawings are strictly followed in the assembly, such as on the alignment between the centers of the impeller's outlet and the guide vane's inlet. the uniform values of the sealing intervals of both rotor and stator portions etc. Covering angle and central line posit ion adjustment. check the equipments at least in the fol lowing three periods and take adjustment: The first time, both pump and foundation are secured while the motor is not. The second time, both pump and motor are secured while the bolts on the suck-in and spitting pipeline flanges are not. The third time is in 24 hours after the pump starts running,then secure both pump and motor

=== CONSTRUCTION FEATURE === Construction feature about Centrifugal High Pressure Multistage Hot Water Pump The Stainless Steel Housing Material and Free standing Installation heat pump swimming pool heater is supported by both ends, and casing portion is sectional. Connected with motor by flexible coupling For rotating direction, viewing from the motor end. 1. The boiler feedwater pumps are sectional casing,multistage centrifugal pumps. The suction casing, stage casing and discharge casings are rigidly held together by tie bolts. The joints between these casings are primarily sealed by means of metal-metal contact. Simultaneously,O-rings are used as auxiliary seals. 2. The shafts of these pumps are sealed by soft-packing and cooling water. Mechanical seal can be used according to the client's requirement. 3. The rotating assembly is supported by sliding bearings on both ends of the pump shaft. Bearings of pump are forced-lubricated. The oil system is equipped for type QD(G) pump The axial thrust of rotor is balanced by balance disc. And the thrust bearing is also provided which is sed to bear residual axial force caused by the change of working conditions. The assembly quality of the boiler feedwater pump will result in a notable affection to the performance and the running stability of it and can not be guaranteed unless the technical requirements in the drawings are strictly followed in the assembly, such as on the alignment between the centers of the impeller's outlet and the guide vane's inlet. the uniform values of the sealing intervals of both rotor and stator portions etc. Covering angle and central line posit ion adjustment. check the equipments at least in the fol lowing three periods and take adjustment: The first time, both pump and foundation are secured while the motor is not. The second time, both pump and motor are secured while the bolts on the suck-in and spitting pipeline flanges are not. The third time is in 24 hours after the pump starts running,then secure both pump and motor

=== OPERATING TIPS === Attentions when operate Centrifugal High Pressure Multistage Hot Water Pump The boiler feedwater pump is allowed to run within the set parameter range only. The pump is not allowed to run with the spitting valve closed or closed to a little opening, or it will be caused heated and duration lowered. Each pump is required to run under the special parameters so as to guarantee the flow of it if mounted in a parallel system. The pump can not run with the suck-in valve closed, or it may be dried moving to cause parts damaged. The medium the pump transports can not contain air or gas, or both flow and head of the pump may not be accurately measured and, meanwhile, grinding maybe produced to damage parts. This pump is not allowed to transport any material with grains, or both pump efficacy and part duration may be lowered. To keep the boiler feedwater pump in a high effective and stable work, it must be often repaired, the items of repair and the interval between every repair depend on the working condition and running state of it. === DRIVER === Driver about Centrifugal High Pressure Multistage Hot Water Pump The boiler feedwater pump is driven by the motor through the coupling The gear, membrane coupling and hydraulic coupling can be used according to client's requirements. The pump can be driven by turbine or motor.The rotating direction of pumps are clockwise when viewed from the driving end.

=== FAQ ===

RFQ about Centrifugal High Pressure Multistage Hot Water Pump

Tips for boiler feed high pressure hot water centrifugal pump installation

Please take note as below when install the high pressure water pump:

1. The preformed hole on the foundation should be poured as the pump installation drawing.

2. The installation level should meet the demand of the allowed vacuum suction height. The foundation should be in horizontal and stable condition, to make sure the rotation of the driver machinery same with the pump in the direction.

3. When connect by coupling, must make sure the pump and driver shaft center should be in a straight line.

4. If belt connection, the shaft center should be in parallel.

5. The boiler feed water pump suction pipe should be sealed well, and try to less the quantity of the elbow and check valve. When fill water, exhausted the air. It should be no any air when operate. We need to keep the suction pipe slopes up slightly, and then connect with the pump inlet.

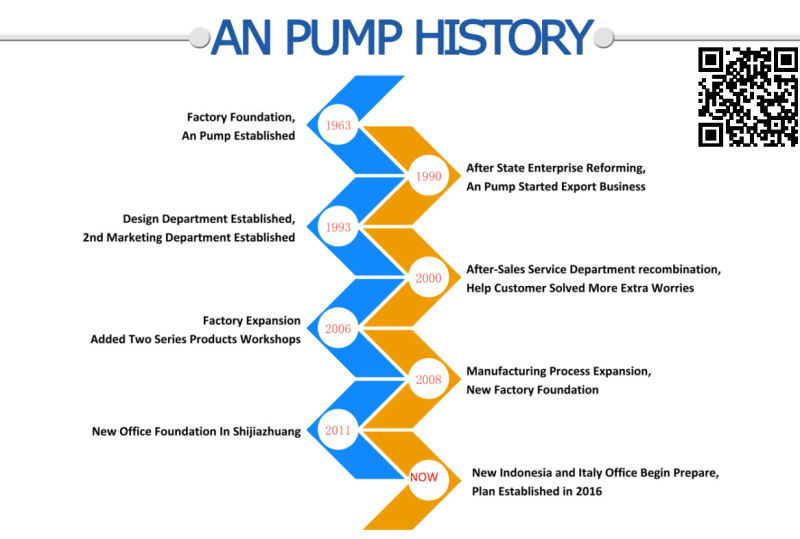

=== OUR HISTORY ===

=== PACKAGING & SHIPPING ===

=== PACKAGING & SHIPPING ===

=== CONTACT US ===

Contact us if you need more details on Multistage Hot Water Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Multistage Water Centrifugal Pump、Boiler Hot Water Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Multistage Hot Water Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Multistage Water Centrifugal Pump、Boiler Hot Water Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

=== GENERALS ===

General about Centrifugal High Pressure Multistage Hot Water Pump

QDG series boiler feed high pressure hot water centrifugal pump is multi-stages centrifugal pump. It used for boiler water feed or other industry hot water supply projects.

QDG series boiler feed hot water centrifugal pump matches the performance, technical requirement and testing method for the international boiler projects.

This series hot water centrifugal pump meet the international standard, with the feature of small volume, good performance, stable and reliable operation, and high efficiency. Besides, it is the best choice for the hot water supply projects.

It included horizontal Boiler Feed Water Pump and vertical boiler Feed Water Pump.

QDG series booster pump is multi-stages centrifugal pump. It used for boiler water feed or other industry hot water supply projects.

QDG series hot water centrifugal pump matches the performance, technical requirement and testing method for the international boiler projects.

This series boiler booster high pressure water pump meet the international standard, with the feature of small volume, good performance, stable and reliable operation, and high efficiency. Besides, it is the best choice for the hot water supply projects.

It included horizontal boiler feed water boiler feed water pump and vertical boiler feed water pump.

=== PARAMETER ===

Performance Range for Centrifugal High Pressure Multistage Hot Water Pump

Flow rate: 3~500m3/h

Head: 70~650m

Pressure: 7~65Bar

Speed: 1450~2950rpm

Max Eff: 90%

=== APPLICATION ===

Application for Centrifugal High Pressure Multistage Hot Water Pump

Aerospace Oil & Gas

Building industry Power Station

Chemical Petro-Chemical

General Industry Pharmaceutical

Marine Pulp & Paper

Mining & Aggregate Water & Waste water

=== ADVANTAGES ===

Advantages of Centrifugal High Pressure Multistage Hot Water Pump

20 years in producing horizontal boiler feed high pressure hot water centrifugal pump

Independent Design

advanced technology from Australia, Canada, America

Specialized Test Equipment

Anti-rust treatment casting

Supply reasonable suggestion for choosing pumps

OEM available

=== PERFORMANCE TABLE LIST ===

Performance Data Sheet for Centrifugal High Pressure Multistage Hot Water Pump

| Pump Type | Flow (m3/h) | Head (m) | Power (KW) | Speed (r/min) |

| QDG 6-25 | 3.75-7.5 | 73.5-306 | 4-11 | 2950 |

| QDG 12-25 | 7.5-15 | 69-338.4 | 5.5-22 | 2950 |

| QDG 12-50 | 7.5-15 | 139.5-648 | 18.5-75 | 2950 |

| QDG 25-30 | 15-30 | 82.5-340 | 15-45 | 2950 |

| QDG 25-50 | 15-30 | 15.78-618 | 22-110 | 2950 |

| QDG 46-30 | 30-55 | 81-340 | 22-75 | 2950 |

| QDG 46-50 | 30-55 | 138-666 | 37-132 | 2950 |

| QDG 85-45 | 55-100 | 78-459 | 37-160 | 2950 |

| QDG 85-67 | 55-100 | 183-666 | 90-250 | 2950 |

| QDG155-67 | 100-185 | 177-684 | 132-400 | 2950 |

| QDG280-43 | 185-335 | 114-423 | 160-450 | 1480 |

| QDG280-65 | 185-355 | 372-680 | 500-800 | 1480 |

| QDG450-60 | 335-500 | 171-650 | 360-1050 | 680 |

=== CONSTRUCTION DRAWING === Construction drawing about Centrifugal High Pressure Multistage Hot Water Pump

=== CONSTRUCTION DRAWING === Construction drawing about Centrifugal High Pressure Multistage Hot Water Pump  === CONSTRUCTION FEATURE === Construction feature about Centrifugal High Pressure Multistage Hot Water Pump The Stainless Steel Housing Material and Free standing Installation heat pump swimming pool heater is supported by both ends, and casing portion is sectional. Connected with motor by flexible coupling For rotating direction, viewing from the motor end. 1. The boiler feedwater pumps are sectional casing,multistage centrifugal pumps. The suction casing, stage casing and discharge casings are rigidly held together by tie bolts. The joints between these casings are primarily sealed by means of metal-metal contact. Simultaneously,O-rings are used as auxiliary seals. 2. The shafts of these pumps are sealed by soft-packing and cooling water. Mechanical seal can be used according to the client's requirement. 3. The rotating assembly is supported by sliding bearings on both ends of the pump shaft. Bearings of pump are forced-lubricated. The oil system is equipped for type QD(G) pump The axial thrust of rotor is balanced by balance disc. And the thrust bearing is also provided which is sed to bear residual axial force caused by the change of working conditions. The assembly quality of the boiler feedwater pump will result in a notable affection to the performance and the running stability of it and can not be guaranteed unless the technical requirements in the drawings are strictly followed in the assembly, such as on the alignment between the centers of the impeller's outlet and the guide vane's inlet. the uniform values of the sealing intervals of both rotor and stator portions etc. Covering angle and central line posit ion adjustment. check the equipments at least in the fol lowing three periods and take adjustment: The first time, both pump and foundation are secured while the motor is not. The second time, both pump and motor are secured while the bolts on the suck-in and spitting pipeline flanges are not. The third time is in 24 hours after the pump starts running,then secure both pump and motor

=== CONSTRUCTION FEATURE === Construction feature about Centrifugal High Pressure Multistage Hot Water Pump The Stainless Steel Housing Material and Free standing Installation heat pump swimming pool heater is supported by both ends, and casing portion is sectional. Connected with motor by flexible coupling For rotating direction, viewing from the motor end. 1. The boiler feedwater pumps are sectional casing,multistage centrifugal pumps. The suction casing, stage casing and discharge casings are rigidly held together by tie bolts. The joints between these casings are primarily sealed by means of metal-metal contact. Simultaneously,O-rings are used as auxiliary seals. 2. The shafts of these pumps are sealed by soft-packing and cooling water. Mechanical seal can be used according to the client's requirement. 3. The rotating assembly is supported by sliding bearings on both ends of the pump shaft. Bearings of pump are forced-lubricated. The oil system is equipped for type QD(G) pump The axial thrust of rotor is balanced by balance disc. And the thrust bearing is also provided which is sed to bear residual axial force caused by the change of working conditions. The assembly quality of the boiler feedwater pump will result in a notable affection to the performance and the running stability of it and can not be guaranteed unless the technical requirements in the drawings are strictly followed in the assembly, such as on the alignment between the centers of the impeller's outlet and the guide vane's inlet. the uniform values of the sealing intervals of both rotor and stator portions etc. Covering angle and central line posit ion adjustment. check the equipments at least in the fol lowing three periods and take adjustment: The first time, both pump and foundation are secured while the motor is not. The second time, both pump and motor are secured while the bolts on the suck-in and spitting pipeline flanges are not. The third time is in 24 hours after the pump starts running,then secure both pump and motor=== OPERATING TIPS === Attentions when operate Centrifugal High Pressure Multistage Hot Water Pump The boiler feedwater pump is allowed to run within the set parameter range only. The pump is not allowed to run with the spitting valve closed or closed to a little opening, or it will be caused heated and duration lowered. Each pump is required to run under the special parameters so as to guarantee the flow of it if mounted in a parallel system. The pump can not run with the suck-in valve closed, or it may be dried moving to cause parts damaged. The medium the pump transports can not contain air or gas, or both flow and head of the pump may not be accurately measured and, meanwhile, grinding maybe produced to damage parts. This pump is not allowed to transport any material with grains, or both pump efficacy and part duration may be lowered. To keep the boiler feedwater pump in a high effective and stable work, it must be often repaired, the items of repair and the interval between every repair depend on the working condition and running state of it. === DRIVER === Driver about Centrifugal High Pressure Multistage Hot Water Pump The boiler feedwater pump is driven by the motor through the coupling The gear, membrane coupling and hydraulic coupling can be used according to client's requirements. The pump can be driven by turbine or motor.The rotating direction of pumps are clockwise when viewed from the driving end.

=== FAQ ===

RFQ about Centrifugal High Pressure Multistage Hot Water Pump

Tips for boiler feed high pressure hot water centrifugal pump installation

Please take note as below when install the high pressure water pump:

1. The preformed hole on the foundation should be poured as the pump installation drawing.

2. The installation level should meet the demand of the allowed vacuum suction height. The foundation should be in horizontal and stable condition, to make sure the rotation of the driver machinery same with the pump in the direction.

3. When connect by coupling, must make sure the pump and driver shaft center should be in a straight line.

4. If belt connection, the shaft center should be in parallel.

5. The boiler feed water pump suction pipe should be sealed well, and try to less the quantity of the elbow and check valve. When fill water, exhausted the air. It should be no any air when operate. We need to keep the suction pipe slopes up slightly, and then connect with the pump inlet.

=== OUR HISTORY ===

=== PACKAGING & SHIPPING ===

=== PACKAGING & SHIPPING ===

=== CONTACT US ===

Contact us if you need more details on Multistage Hot Water Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Multistage Water Centrifugal Pump、Boiler Hot Water Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Multistage Hot Water Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Multistage Water Centrifugal Pump、Boiler Hot Water Pump. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Multistage Pump > Others Multistage Pump

Premium Related Products

Other Products

Hot Products

Centrifugal Zj Horizontal and Zjl Vertical Slurry PumpGravel Sand Pump for Dredger Mud PumpCentrifugal Mining Vertical Slurry Sump PumpHigh Pressure Boiler Feed Water PumpHeavy Duty High Pressure Mining Metal Lined Sludge Slurry PumpCentrifugal Horizontal High Pressure Multistage PumpSand Gravel Pump Marine Dredger Mud PumpHigh Abrasion and Corrosion Resistance Slurry PumpMultistage Centrifugal Water PumpFgd Pump (TLR)Stainless Steel Chemical Pump (IH)Pump AccessoriesFroth Slurry Pump for MiningDredger Gravel Slurry PumpPn Pnl Single Stage Single Suction Mud PumpPw, Pwl High Pressure Machinery Sewage Single Stage Centrifugal Pump