Wear Resistant Gravel Pump

Product Description

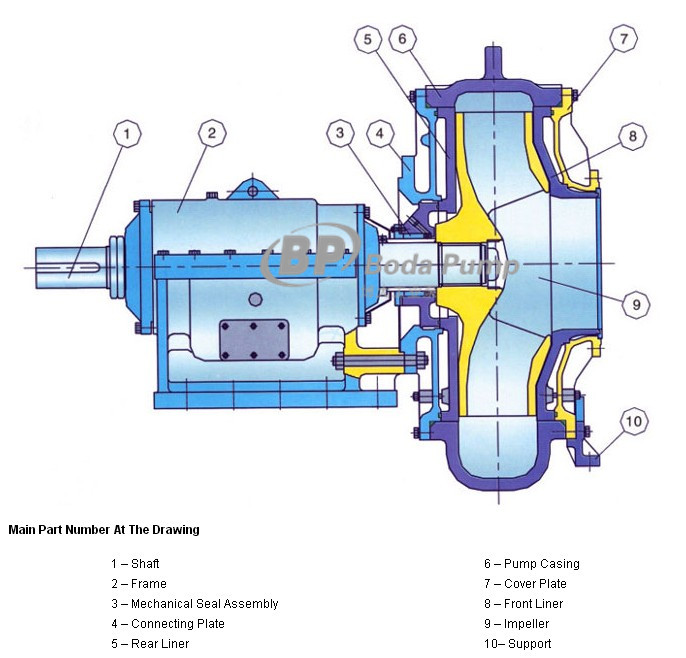

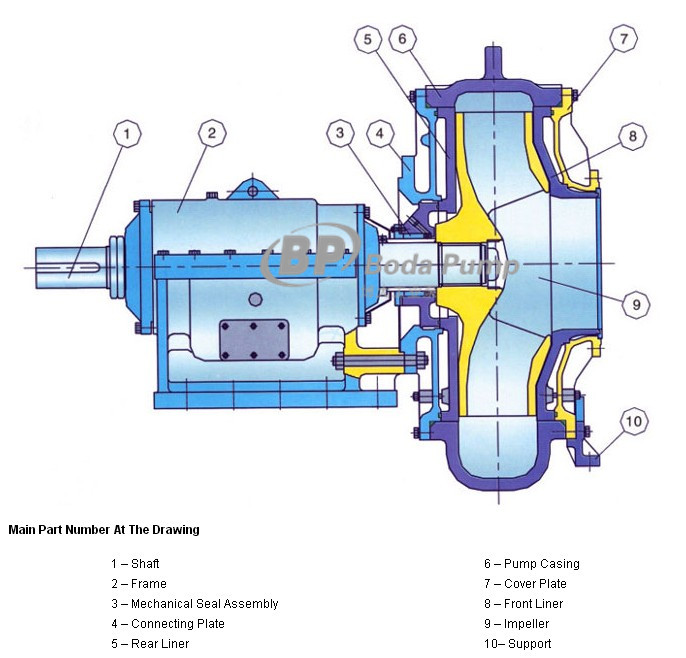

Impeller Number: Single-Stage Pump Influent Type of Impeller: Single Suction Pump Material: A05 Origin: Shijiazhuang Working Pressure: High Pressure Pump Position of Pump Shaft: Horizontal Pump Trademark: Boda Introduction: BG/BGH gravel pump

Long service life,high efficiency

Good quality with favourable price

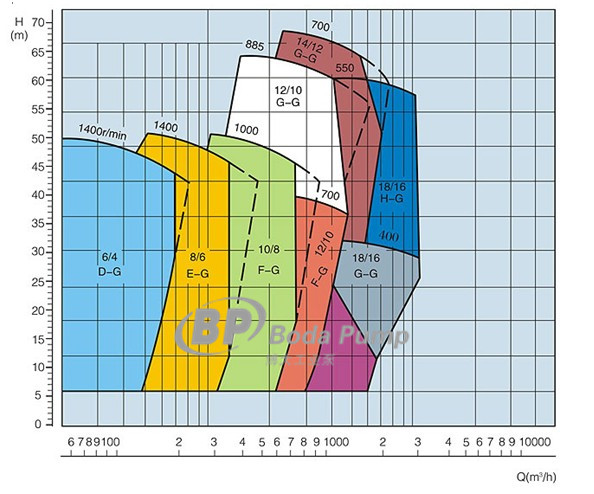

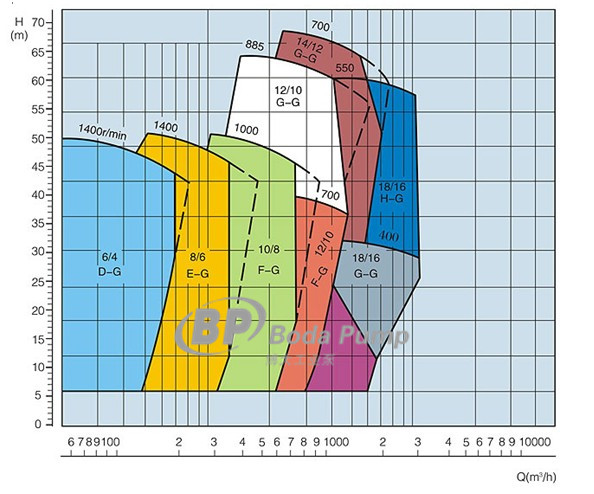

High hardness,anti-wear alloy cast iron Sand suction pump : Constructin of this pump is of single casing connected by means of clamp bands and wide wet passage. The wet parts are made of Ni hard and high chromium abrasion resistance alloys. The discharge direction of pump can be oriented in any direction of 360 degree. This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance. Sealing forms: packing gland, expeller seal, mechanical seal. Driving type: V belt drive, hydraulic coupling drive, fluid coupling drive, frequency conversion drive devices, thyrister speed regulation ect. They are suitable for delivering slurries in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type BGH pumps are of high head ones. Features: 1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump 2) High head, large capacity, high efficiency. 3) Good NPSH performance. 4) Widely application: they are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, Sugar beet , explosive sludge in metal melting, grudging in dredger and course of river and other fields. 5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 6) Wear resistant wet parts: the wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy). 7) Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 9) Centrifugal seal, mechanical seal and packing seal are available. 10) The pump can be directly matched with either motor or diesel engine More specification: It can be equipped with diesel engines or be equipped with motor driven directly. It has the advantages of working stability, little vibration, low noise and low hydraulic loss, high efficiency, low fuel consumption and small size, light weight, simple structure, easy maintenance.

Contact us if you need more details on Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Slurry Pump、Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Long service life,high efficiency

Good quality with favourable price

High hardness,anti-wear alloy cast iron Sand suction pump : Constructin of this pump is of single casing connected by means of clamp bands and wide wet passage. The wet parts are made of Ni hard and high chromium abrasion resistance alloys. The discharge direction of pump can be oriented in any direction of 360 degree. This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance. Sealing forms: packing gland, expeller seal, mechanical seal. Driving type: V belt drive, hydraulic coupling drive, fluid coupling drive, frequency conversion drive devices, thyrister speed regulation ect. They are suitable for delivering slurries in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type BGH pumps are of high head ones. Features: 1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump 2) High head, large capacity, high efficiency. 3) Good NPSH performance. 4) Widely application: they are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, Sugar beet , explosive sludge in metal melting, grudging in dredger and course of river and other fields. 5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 6) Wear resistant wet parts: the wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy). 7) Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 9) Centrifugal seal, mechanical seal and packing seal are available. 10) The pump can be directly matched with either motor or diesel engine More specification: It can be equipped with diesel engines or be equipped with motor driven directly. It has the advantages of working stability, little vibration, low noise and low hydraulic loss, high efficiency, low fuel consumption and small size, light weight, simple structure, easy maintenance.

Contact us if you need more details on Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Slurry Pump、Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Gravel Dredger Pump

Premium Related Products

Other Products

Hot Products

Centrifugal Zj Horizontal and Zjl Vertical Slurry PumpGravel Sand Pump for Dredger Mud PumpCentrifugal Mining Vertical Slurry Sump PumpHigh Pressure Boiler Feed Water PumpHeavy Duty High Pressure Mining Metal Lined Sludge Slurry PumpCentrifugal Horizontal High Pressure Multistage PumpSand Gravel Pump Marine Dredger Mud PumpHigh Abrasion and Corrosion Resistance Slurry PumpMultistage Centrifugal Water PumpFgd Pump (TLR)Stainless Steel Chemical Pump (IH)Pump AccessoriesFroth Slurry Pump for MiningDredger Gravel Slurry PumpPn Pnl Single Stage Single Suction Mud PumpPw, Pwl High Pressure Machinery Sewage Single Stage Centrifugal Pump